Project Description

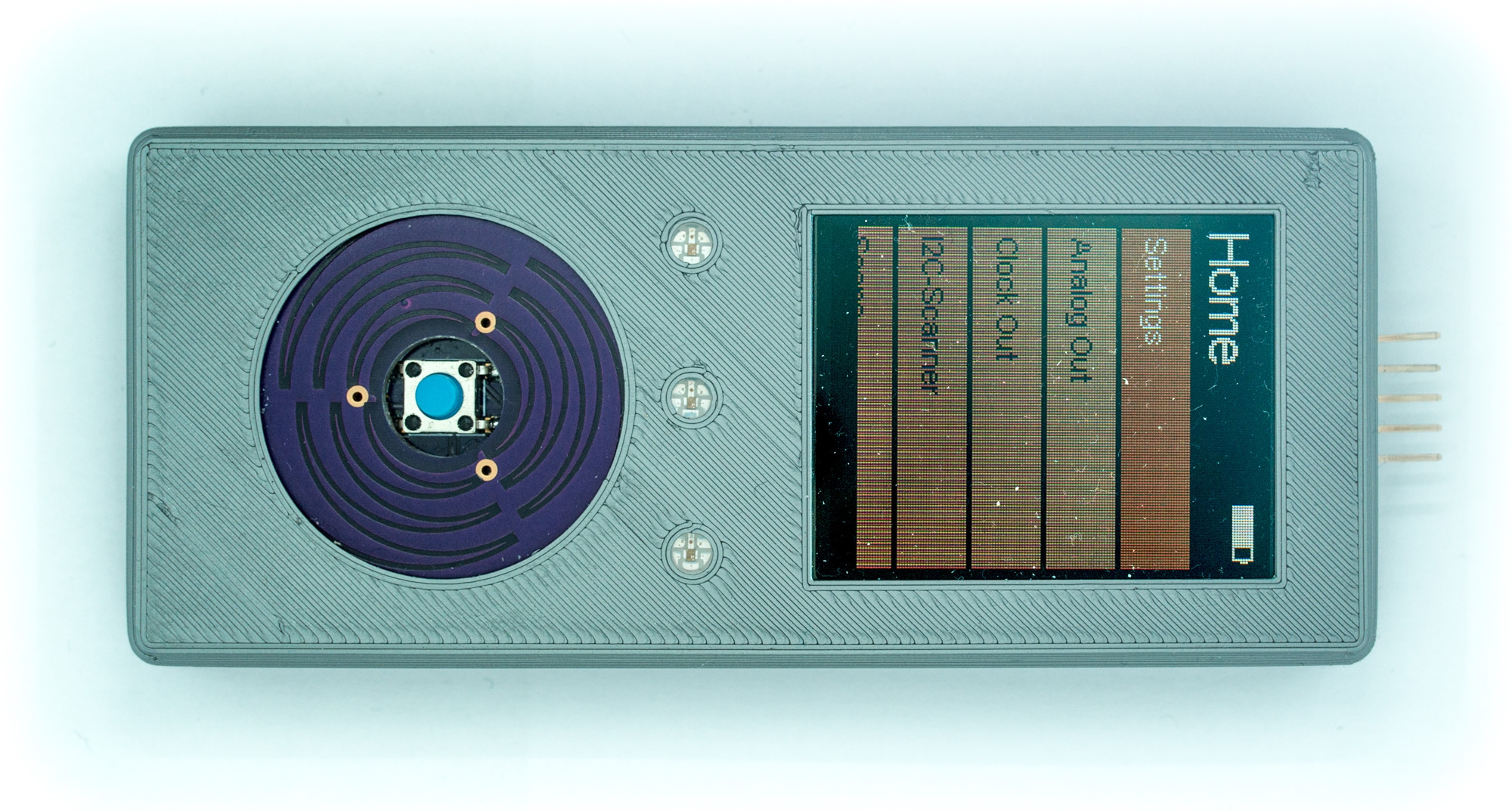

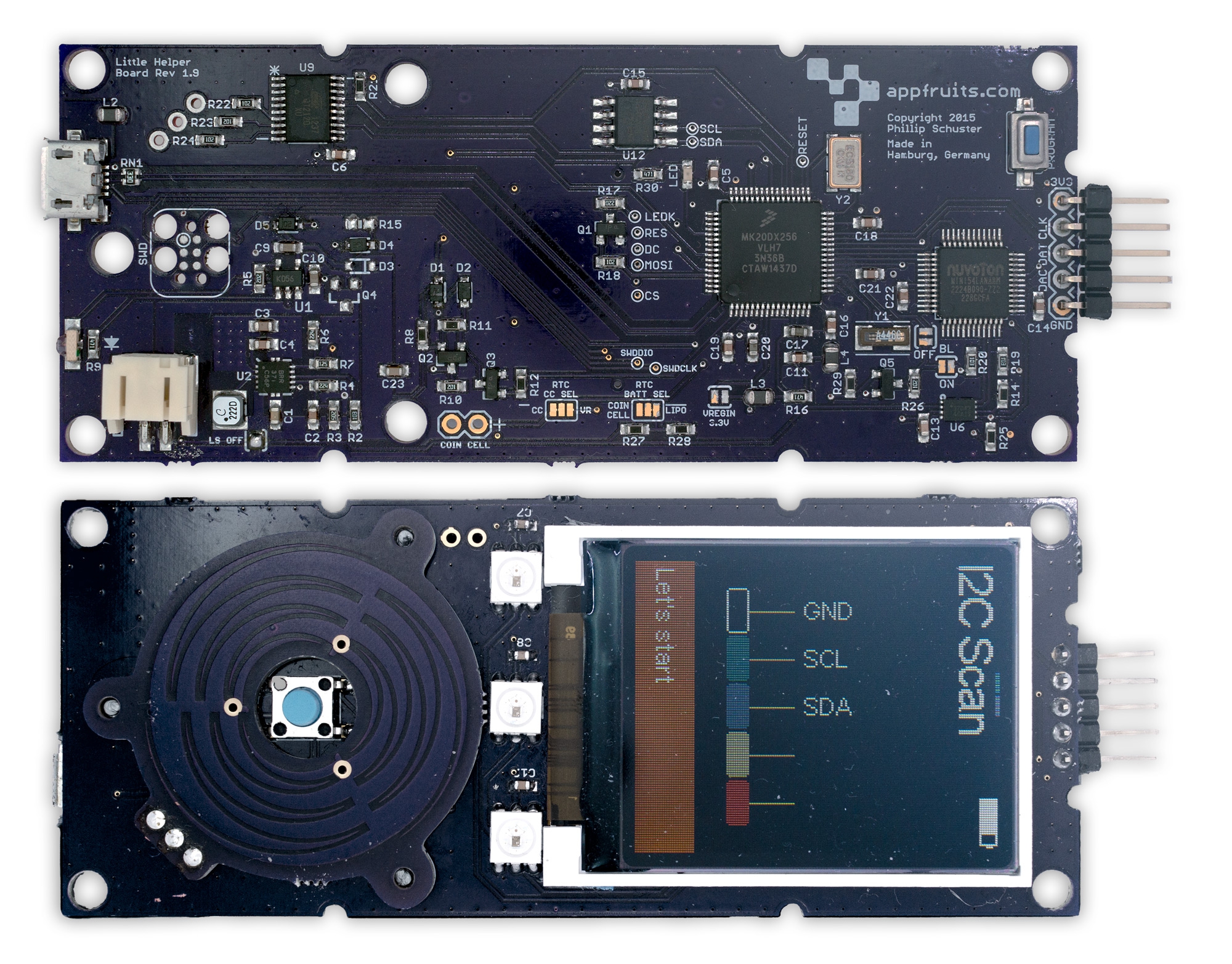

This is a little device we developed at Appfruits. When we developed Copper we needed a project to test its functionality and usefulness with a real world project. Little Helper was born. This little device is based on our previous work with “Custom Teensy” and its purpose is to act as an all around helper in any electronics lab.

Open-Source Hardware

We wrote a blog post about Little Helper if you’re interested in this project or building your own. In this blog post we describe the details and provide anything from PCB schematics and layout, BOM, 3D model of enclosing to 3D print yourself and of course the complete Source Code for the firmware.

Managing Datasheets

We managed to create this project with just one iteration of the PCB! Copper did help us finding footprint bugs and we managed all Datasheets with it. This is great help, especially when developing the firmware. Little Helper features a custom capacitive touch based click wheel based on an Atmel QTouch IC. We had to develop the driver ourselves as we did not find one that did what we wanted. Having access to the Datasheet and Bookmarks we set inside the Datasheet has been great help, as we did not have to constantly fight Finder and the Preview app to find and load the Datasheet and navigation around until we have found specific information we had found already numerous times before.

Part Sourcing

Of course we managed all Parts with Coppers Part Sourcing Technology based on a deep integration of Octopart.com. World’s largest part database. After building the Schematics and the layout we found “real parts” for the footprints using Copper Part Sourcing tools. We chose Mouser as our primary distributor and found and attached one part after the other. We only had to do this once. No struggling with Excel/Numbers Sheets and Copy & Paste horror. Find, click, attached. And you’ll never loose that connection again.

Connected Prices & Availability

What I really love is Coppers BOM-Tool. I really hate Part Sourcing and managing BOM lists. All this is gone using Copper. After we had attached real parts we could see with a click on the BOM mode which parts were available at the major distributors and how much they cost.

Although a few parts were cheaper at Digi-Key, we chose to use Mouser for all parts as shipping fee would kill any benefit of slightly lower prices for a few components. Without Copper you would need to use Eagles BOM export-tool. Enter Part numbers. Upload them to Octopart or your distributors to compare prices. Between these steps is a lot of upload to websites, finding files on your hard disk, Copy & Paste. With Copper it’s one click.

We had this project lying around for a few months to invest time in fixing bugs and optimizing performance of the application. I loaded Little Helper in Copper, started BOM-Tool. Voila, everything there and I am ready to order new parts. Before Copper, I would have a few BOM lists lying around (I am not good with disciplined file management) and I would ask myself which one is the latest. I would check shipping lists of Mouser to compare until I have found the correct BOM. All that is gone with Copper!

Iteration Less Design Made Possible

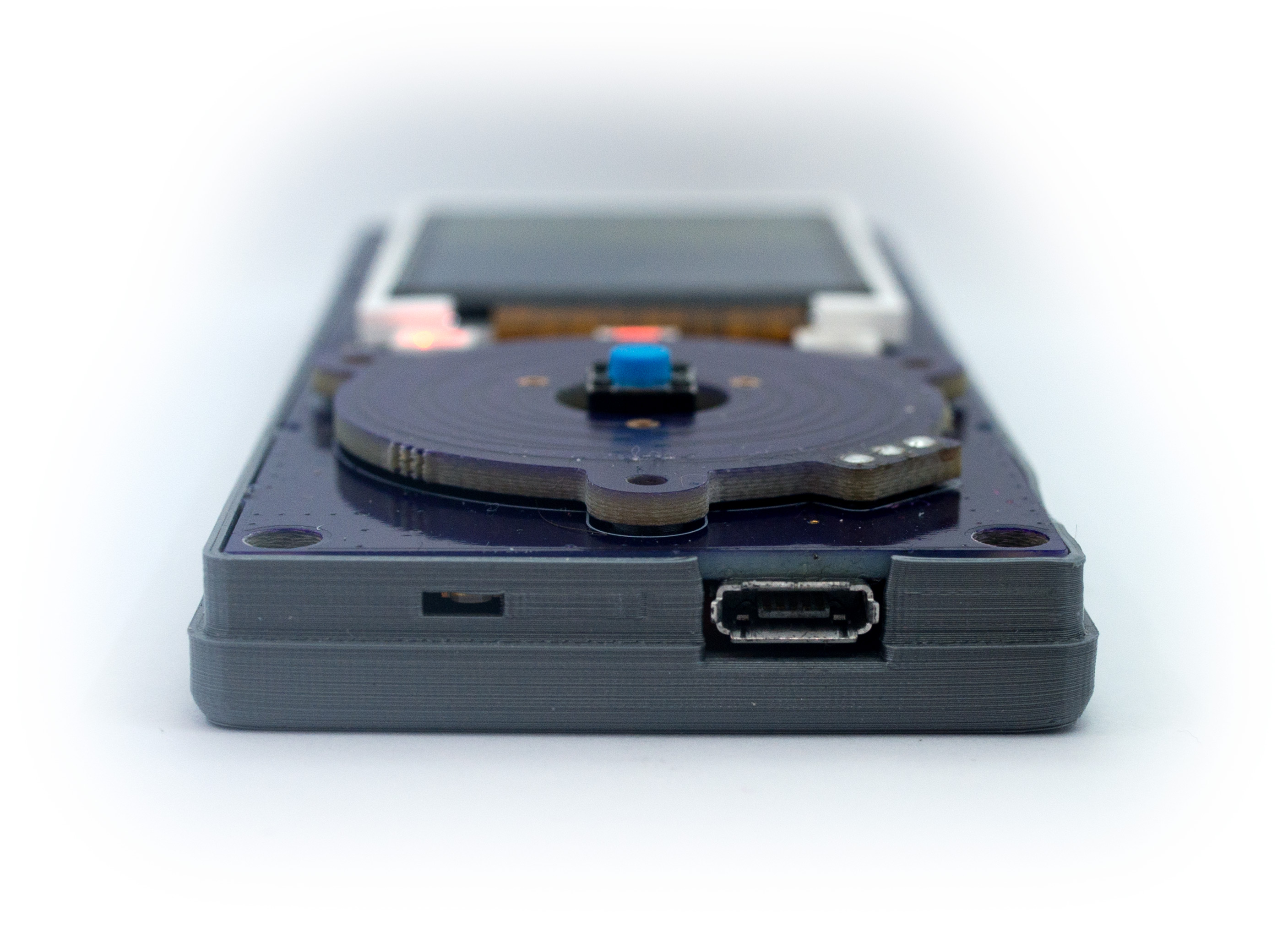

As you can see in the pictures above we wanted to build a useful device. A useful device must have an enclosing. We created the 3D PCB of Copper in a few minutes using Coppers part database. We had to reposition the USB port a few times. Updating the 3D model is nothing more than changing the position of the device in Eagle and save. Copper will recognize the design changed and will update its internal database immediately. The 3D model is refreshed immediately, too!

We exported the 3D model as a Collada file and imported it into Fusion 360. If you modify positions of your parts, i.e. USB connectors, you can upload a new version to Fusion, and if you imported the PCB as a referenced model to Fusion 360 it will also refresh inside your enclosing project. As the parts we use in Copper are directly from the manufacturers they are very, very precise in dimension and form. We were able to build a very tight enclosing in only one 3D print iteration! That is amazing. Everything fits perfectly!

Download

If you are interested in Copper or have just started using Copper it makes sense to play around with a ready to use design. Little Helper has been made public to provide just that: Download the Eagle files along the .cop file that keeps all settings, from real parts, datasheet bookmarks and 3D scenes and settings.

Did you notice how small it is? And that it does not contain any textures, 3D models, etc.? Everything is build on the file, by the few meta data that are saved along your Eagle files. This makes sharing a snap.

If anyone builds another BOM, let’s say optimized for part availability in Japan, then you would just replace the .cop file and would have the fully functional BOM! 3D models are hosted in the Copper Cloud and are downloaded on demand, automatically by Copper.

Showcase your Project

If you want to showcase your project exporting rendered 3D images from Copper is an awesome way to do it. Check out our blog post as an example on how to do that.

When You open Little Helper in Copper, you can switch click on the presets in Scene Inspector. Copper will nicely animate between the presets. We are working on exporting such an animation as a video you might use as a base for a nice promotional video. Drop us a line if you are interested in this feature.

Leave A Comment